In the world of food safety, every nonconformity—whether small or big—can pose a serious risk to consumers and damage a brand’s reputation. That’s why Correction, Corrective Action, and Preventive Action (CAPA) play a vital role in food safety management systems such as ISO 22000, FSSC 22000, BRCGS Food Safety, and IFS Food. Understanding the differences between these three terms is critical for maintaining compliance, avoiding food safety hazards, and ensuring continuous improvement.

This article will break down what each term means, how they are applied in practice, and why they matter for your food business.

What is a Correction in Food Safety?

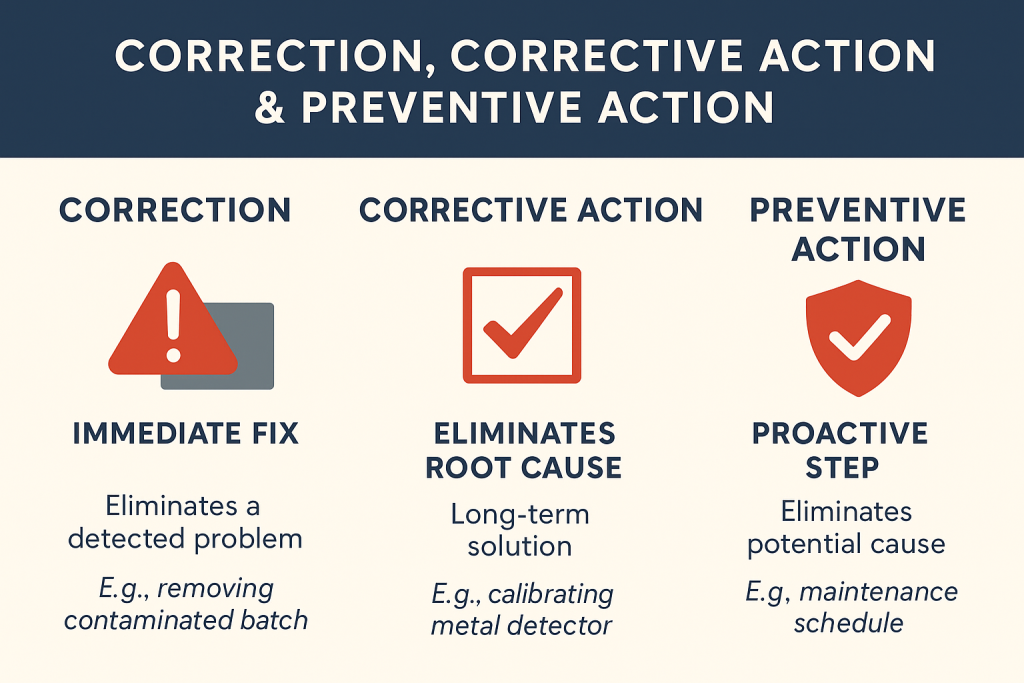

A Correction is an immediate fix to eliminate a detected nonconformity.

-

It does not address the root cause.

-

It only fixes the problem at hand.

Example:

If a metal detector rejects a contaminated product, removing the affected batch from the production line is a correction.

In ISO 22000, FSSC 22000, BRCGS, and IFS Food standards, corrections are required as a first response to prevent unsafe products from reaching consumers.

What is a Corrective Action in Food Safety?

A Corrective Action goes deeper. It is a long-term solution taken to eliminate the root cause of a detected nonconformity to prevent its recurrence.

Steps usually include:

-

Identifying the root cause (e.g., using root cause analysis tools like 5 Why’s or Fishbone diagram).

-

Implementing corrective actions.

-

Verifying effectiveness.

Example:

If the metal detector failed because of poor calibration, calibrating the detector, training staff, and implementing a monitoring plan would be corrective actions.

Why it matters:

-

In ISO 22000 & FSSC 22000, corrective actions are required to ensure continuous improvement.

-

In BRCGS Food Safety & IFS Food, corrective actions are audited rigorously and linked to nonconformity grading.

What is a Preventive Action in Food Safety?

A Preventive Action is a proactive step taken to eliminate the potential cause of a possible nonconformity before it occurs.

Example:

Introducing a maintenance schedule for all critical control equipment (such as metal detectors and X-ray machines) to prevent failures before they happen.

Key point:

-

ISO 22000:2018 integrates preventive action into risk-based thinking and Hazard Analysis.

-

FSSC 22000, BRCGS, and IFS Food all emphasize preventive action as part of risk assessment and food safety culture.

Key Differences Between Correction, Corrective Action & Preventive Action

| Term | Meaning | Example | Goal |

|---|---|---|---|

| Correction | Immediate fix to a detected problem | Removing contaminated batch | Quick containment |

| Corrective Action | Eliminates root cause of a problem | Calibrating and monitoring metal detector | Prevent recurrence |

| Preventive Action | Proactive measure before an issue happens | Maintenance schedule for metal detectors | Prevent occurrence |

Why CAPA is Essential for Food Businesses

Implementing Correction, Corrective Action, and Preventive Action is not just about certification—it’s about protecting your consumers and your brand.

✅ Helps achieve compliance with ISO 22000, FSSC 22000, BRCGS, and IFS Food.

✅ Strengthens food safety culture.

✅ Reduces risks of product recalls.

✅ Builds trust with regulators, buyers, and consumers.

Conclusion

In food safety management systems, Correction, Corrective Action, and Preventive Action work together as a powerful trio to safeguard your operations. By applying them correctly, your business not only meets the requirements of ISO 22000, FSSC 22000, BRCGS Food Safety, and IFS Food, but also ensures a culture of continuous improvement and consumer protection.